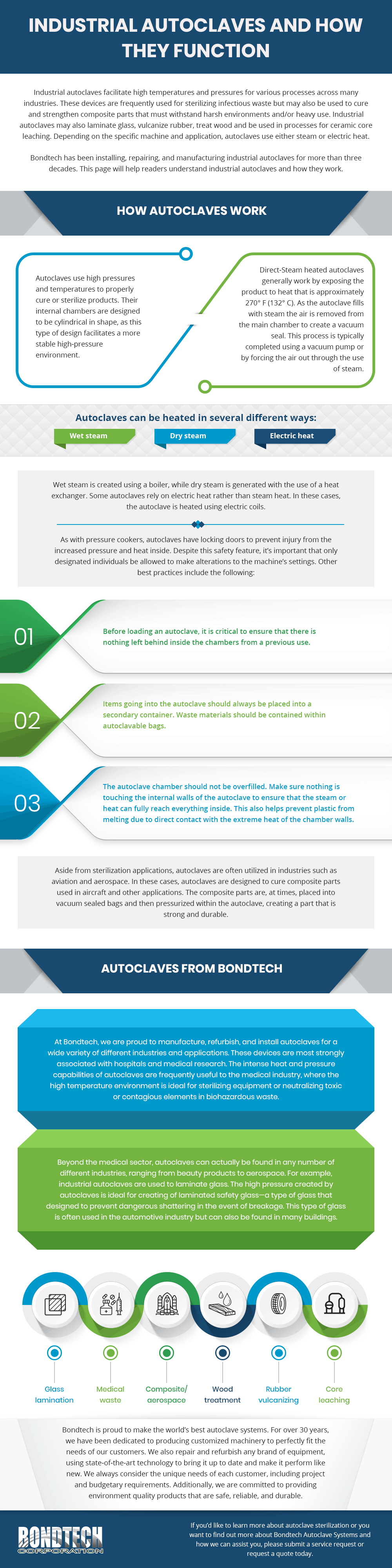

Industrial autoclaves facilitate high temperatures and pressures for various processes across many industries. These devices are frequently used for sterilizing infectious waste but may also be used to cure and strengthen composite parts that must withstand harsh environments and/or heavy use. Industrial autoclaves may also laminate glass, vulcanize rubber, treat wood and be used in processes for ceramic core leaching. Depending on the specific machine and application, autoclaves use either steam or electric heat.

Bondtech has been installing, repairing, and manufacturing industrial autoclaves for more than three decades. This page will help readers understand industrial autoclaves and how they work.

How Autoclaves Work

Autoclaves use high pressures and temperatures to properly cure or sterilize products. Their internal chambers are designed to be cylindrical in shape, as this type of design facilitates a more stable high-pressure environment.

Direct-Steam heated autoclaves generally work by exposing the product to heat that is approximately 270° F (132° C). As the autoclave fills with steam the air is removed from the main chamber to create a vacuum seal. This process is typically completed using a vacuum pump or by forcing the air out through the use of steam. Autoclaves can be heated in several different ways:

- Wet steam

- Dry steam

- Electric heat

Wet steam is created using a boiler, while dry steam is generated with the use of a heat exchanger. Some autoclaves rely on electric heat rather than steam heat. In these cases, the autoclave is heated using electric coils.

As with pressure cookers, autoclaves have locking doors to prevent injury from the increased pressure and heat inside. Despite this safety feature, it’s important that only designated individuals be allowed to make alterations to the machine’s settings. Other best practices include the following:

- Before loading an autoclave, it is critical to ensure that there is nothing left behind inside the chambers from a previous use.

- Items going into the autoclave should always be placed into a secondary container. Waste materials should be contained within autoclavable bags.

- The autoclave chamber should not be overfilled. Make sure nothing is touching the internal walls of the autoclave to ensure that the steam or heat can fully reach everything inside. This also helps prevent plastic from melting due to direct contact with the extreme heat of the chamber walls.

Aside from sterilization applications, autoclaves are often utilized in industries such as aviation and aerospace. In these cases, autoclaves are designed to cure composite parts used in aircraft and other applications. The composite parts are, at times, placed into vacuum sealed bags and then pressurized within the autoclave, creating a part that is strong and durable.

Autoclave Frequently Asked Questions

At Bondtech Corporation, we have been manufacturing reliable, high quality autoclaves for over 30 years. Here are some frequently asked questions:

What sizes do you provide?

We provide all standard sizes. We manufacture our autoclaves at our own facilities, so we are also able to provide custom sizes to suit the needs of unique or demanding applications.

How long does an autoclave take to sterilize equipment and supplies?

Sterilization times vary depending on the equipment in question and the needs of your particular project. For medical waste, the entire sterilization process takes about one hour from beginning to end, with about 15 minutes dedicated to setup and removal, and 45 minutes of actual sterilization.

Where is your manufacturing facility located?

Our headquarters are located in Somerset, Kentucky. We operate manufacturing facilities located in Charlotte, North Carolina, and Salisbury, North Carolina.

What items or materials should not be autoclaved?

While autoclaves are convenient and necessary for a number of industries, there are certain materials that should never be autoclaved. These include:

- Reactive or toxic materials such as radioactive waste or chemotherapy waste

- Toxic and flammable items such as polystyrene, polyethylene, and polyurethane

- Explosive materials such as liquids in sealed containers, which may explode under the pressure of the autoclave

- Corrosive materials such as bleach or hypochlorite

How much do autoclaves cost?

The production process for autoclaves is highly customizable, so costs may vary wildly depending on your specific project needs. Please request a quote for a quick and accurate estimate for your use case.

Can you work on other model autoclaves?

Yes, we work with autoclaves from any global manufacturer. Our services include, but not limited to, refurbishing of these systems as well as maintenance and repairs as needed.

Autoclaves from Bondtech

For over 30 years, we have been dedicated to producing customized machinery to perfectly fit the needs of our customers. We also repair and refurbish any brand of equipment, using state-of-the-art technology to bring it up to date and make it perform like new. We always consider the unique needs of each customer, including project and budgetary requirements. Additionally, we are committed to providing environment quality products that are safe, reliable, and durable.

If you’d like to learn more about autoclave sterilization or you want to find out more about Bondtech Autoclave Systems and how we can assist you, please submit a service request or request a quote today.