Featured

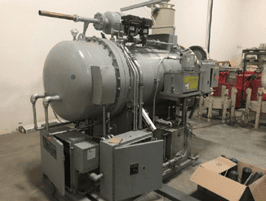

Bondtech BCT5x12 – NB# 1317

5’ ID x 12’ Long

Design pressure: 165psig

Operating pressure: 150psig

Design/operating temperature: 500 deg. F

(12) Thermocouple Jacks

(6) Automated vacuum lines

(1) 2HP Vacuum Pump

Allen Bradley CompactLogix PLC

Electric Heat with internal insulation

Complete and ready for immediate sale!

Bondtech 10×24 DD Autoclave (as-is, where-is) NB# 682

120” ID x 24’ long Autoclave with the following parameters:

– Quick Opening Double Door

– Design Pressure: 150 PSIG Full Vacuum

– Design temperature: 366 Deg. F

– Carbon Steel

– Vulcanizer nozzle set per Dwg# C57854

– Track supports

– 1/8” Corrosion Allowance

– Approx weight: 75,000lbs

Includes Allen Bradley CompactLogix PLC controls:

– Electrical Control Panel

– Controlled Heated Ambient – 330 Deg. F.

– Total Automatic Control of Cycle Sequences from Beginning to End

– Operator Controls for Locking Door

– Process Complete and Ready to Open Door Indicator Lights

– Temperature and Pressure Safety Back Ups

– Full Program Editing and Storage Capabilities

– 17” Fanless Touch PC w/ Intel Atom 1.6 Ghz HMI with Wonderware Intouch Software

– Proportional Steam Valve

– Steam Traps

– 2” External Insulation with White Aluminum Covering

– Note: Controls will provide a Saturated Wet Steam Environment in the autoclave

Manufacturer: Melco Steel NB# 889

Dimensions: 8’ ID x 20’ Long (working area)

Maximum Temperature: 650 Deg. F.

National Board: Certified, #889

Date of Manufacturing: 1996

Misc: System is currently located in Salisbury, NC.

Does NOT include controls – SEE NOTES

- Recommend having the system fully inspected to test heating elements, check cooling coil for leaks/corrosion, etc.

- Recommend having insulation replaced inside autoclave due to previous operation in glass lamination

- Recommend new PLC controls, power cabinet, etc. to start refurbishing system

- Bondtech can provide a quote for all of the above and offer a turnkey operational system upon request

Manufacturer: South Gate Engineering – NB# 11063

Dimensions: 9’ ID x 16’ Long (working area)

National Board: Certified, #11063

Date of Manufacturing: 2006

Misc: System is currently located in Salisbury, NC.

Does NOT include controls – SEE NOTES

- Recommend having the system fully inspected to test heating elements, check cooling coil for leaks/corrosion, etc.

- Recommend having insulation replaced inside autoclave due to previous operation in glass lamination.

- Recommend new PLC controls, power cabinet, etc. to start refurbishing the system

- Bondtech can provide a quote for all of the above and offer a turnkey operational system upon request

Used/Refurbished TEC NB# 436

35.25” ID x 5’ 8-7/8” Long with Quick Opening Manual Side Swing Door.

– 165 PSIG @ 400 Deg F.

– 1/32” Corrosion allowance.

Refurbish TEC NB436:

- Inspect fan, fan motor dome, and fan motor. (Done)

- Inspect approximately?? KW heater. (Done)

- Inspect cooling coil. (Done)

- Inspect door pump & controls. (Done)

- Clean and repaint autoclave.

- Recertify Safety Relief valve.

- Inspect chamber pressure control valves. (Done)

- Inspect cooling water flow control valves. (Done)

Install new:

- New Smart SCR heat control and power panel.

- Pneumatic control panel.

- Vacuum manifold with controls.

- 2 vacuum source lines each with:

– Two motorized ball valves

– Manual ball valve

– Pressure gauge

- 2 Vacuum probe lines each with:

– Transducer with data collection

– Three-way ball valve for transducer calibration

- UL listed control panel w/ Allen Bradley Compactlogix PLC Controls & Panel Mounted 17” Fanless Touch Industrial PC HMI W/3.40GHz Intel Core i5-Processor, 8GB DDR3 1600MHz System Memory, 1280 x 1024 resolution, and Microsoft Windows 7 (64 Bit) Professional Operating System.

System is mounted on a skid additional time and labor is required to make brackets, redo conduit/wiring, mount vacuum pump and fit new cabinets on structure.

ALLEN BRADLY SOFTWARE and programming by Bondtech.

Price is based on reuse of fan, fan motor, door pump, insulation, cooling coil, heat exchanger, cooling water pump, and heat coil, without repair. If during refurbishing of autoclave these are found to be defective, CUSTOMER will be notified and quote for repair or replacement will be issued.

Delivery: 8-10 weeks ARO Purchase Order/Down Payment

NOTE: System is partially complete with most items listed above. Please call for further details and information on this system.

Bondtech 23-Tire – NB# 17

Manufacturer: Bondtech

Model: Salisbury 23 Tire

Date of manufacture: 1998

National Board #: 17

Working area: 5’ ID x 23’ Long

Electrical: 460v, 60hz

Special Notes: This system is complete and ready for immediate sale. Currently located at our facility in Salisbury, North Carolina

Sale Price: (As-is, Where-is)

Inspection visits are welcomed and encouraged

SCHOLZ 3X9 AUTOCLAVE – NB# 108

MFG: SCHOLZ

YEAR: 1986

NATIONAL BOARD CERTIFIED: # 108

DESIGN PRESSURE: 254 PSI

DESIGN TEMP: 302 DEG. F

HEAT: INDIRECT STEAM

COOLING: WATER COOLED

ELECTRICAL CONTROLS: TEMP CONTROLLER WITH CHART RECORDER

FAN: ELECTRIC FAN WITH SPARE FAN MOTOR

MISC: FLAT TRAY MEASURING 27″ WIDE X 75″ LONG

BEING SOLD AS-IS. LOCATED AT OUR PLANT IN SALISBURY, NC

FOR MORE INFORMATION PLEASE CALL AT 606-677-2616 OR EMAIL SALES@BONDTECH.NET

BONDTECH 3X3 STAINLESS STERILIZER – NB# 195

MFG: FAI/BONDTECH

YEAR: 2001

SIZE: 3′ ID X 3′ LONG

MATERIAL: SA240 304L STAINLESS STEEL

DESIGN PRESSURE: 75 PSIG

DESIGN TEMP: 500 DEG. F

BTT105: One (1) Bondtech 3’ dia x 3’ long Autoclave.

Number of bins: 1/load

Bin Dimensions: 2.33”l X 2.33’ w X 2’ h

Cycle time: 45 minutes (load to load)

INSULATION

The exterior of the autoclave will be insulated with 2” of fiberglass, which will be covered with a white aluminum jacket to protect the insulation, and to make sure the equipment can be kept clean Some surfaces will not be insulated, such as the door locking ring and hinge mechanism, support saddles, etc. These exposed surfaces will be painted with industrial enamel if fabricated from carbon steel.

PROCESS VALVES

Complete with the process valves including steam supply, pressure vent and safety relief. The steam inlet valve is to maintain and control steam pressure. For safety, the steam inlet valve is a normally closed valve that closes in the event of any power loss.

MATERIAL HANDLING: RAMP/TRACK SYSTEM

Tracks are provided at the bottom of the autoclave to match the ramp section. Ramp is designed and positions for simple loading and unloading of the autoclave vessel.

SYSTEM PIPING.

The autoclave system will completely piped at the factory prior to shipment for simple installation. The system piping will consist of the following:

- Condensate Drains Steam traps (2) – front and rear steam traps maintains the vessel free of condensate.

- Thermocouple connections.

- Steam Inlet Valve/Strainer – proportionally controlled steam inlet valve for smooth and Accurate control of steam pressure inlet. Steam inlet valve is controlled by a PID loop controlled by the PLC.

CONTROL SYSTEM/PROCESS VALVES/CONTROL PANEL & INSTRUMENTATION

The autoclave control panel is package in a NEMA 12 rated panel. The autoclave system is controlled by a state-of-the-art “Super Micro” Programmable Logic Controller (PLC) with modem hookup capabilities for online support. The PLC performs automatic sterilization control control that includes pre-vacuum, pressurization/heat soak, vent and post-vacuum. The PLC monitors pressure vessel conditions for providing safety interlock for door operation.

SUPERMICRO PROGRAMMABLE LOGIC CONTROLLER (PLC).

Allen Bradley SLC504 programmable control system for autoclave with the following features:

- Controlled heating 0-300 Deg. F at 0-99 Deg./min F

- Run at precise temperature 0-300 Deg. F for programmed period of time

- Total automatic control of cycle sequences from beginning to end

- Operator controls for locking door

- Process complete and ready to open door indicator lights

- Temperature and pressure safety back ups

- User friendly keypad

- Full program editing and storage capabilities

- LCD display

- Multi pen circular chart recorder for temperature and pressure

- A Network communications port may be used to remotely monitor the system

- Strip chart recorder

HEAT:

Saturated steam

STEAM GENERATOR

LB-40H steam outputting rating; 138 lbs/hr from and at 212 F to 100 PSI WITH 4 bhp, ELECTRICAL POWER; 40 KW, 460 VOLTS, 3 PHASE, 60 Hz, approximately 53 Amp for heater elements; 120 volt single phase required for controls. This generator is complete with motorized automatic flush and drain, and with a 5 micron water filter

FOR MORE INFORMATION PLEASE CONTACT US AT 606-677-2616 OR VIA EMAIL AT SALES@BONDTECH.NET</a

BANDAG 5X19 AUTOCLAVE – NB# 466

MFG: BANDAG

NATIONAL BOARD CERTIFIED: #466

SIZE: 5′ X 19′

YEAR: 1971

DESIGN PRESSURE: 100 PSI

DESIGN TEMPERATURE: 195 DEG. F

Vessel can be used as a dry heat vulcanizer or low temp. composite system. Does have a davit style swing door.

FOR MORE INFORMATION PLEASE CALL US AT 606-677-2616 OR EMAIL AT SALES@BONDTECH.NET</a

used autoclaves BONDTECH 18X24 VERTICAL AUTOCLAVE – NB# 753

Manufacturer: Bondtech Corporation

National Board #: 753

Size: 18″ x 24″ deep (work space) vertical

Design Pressure: 710 PSIG Operating Pressure: 700 PSIG

Design Temperature: 600 Deg. F

Material: Carbon steel with electro less nickel coating

Door: Manual bolted (24 nuts) door to access work space; hydraulic arm to lift up and rotate to clear work space.

Insulation: External insulation to minimize heat loss and operator hazard

Heating: Externally mounted strip heaters rated at 36 KW, 480 V/3 phase.

Cooling: Accomplished by microprocessor causing cooling inlet solenoid valve to pen, allowing cooling water to flow through tubing to transfer heat from pressure vessel.

Vacuum: One 1/2″ NPT vacuum source in work zone.

Controls: Nema 12 control panel with connection requirement of 480 v, 3 phase, power and yokigama UT 35 microprocessor with programmable controller, temperature hi-limit controller, all required relays, contactors, starters, pushbuttons, indicator lamps, fusing and overload protection.

Thermocouple: One thermocouple, vessel mounted to provide input to hi-limit controller.

Heat up rate: 770 Deg. F to 500 Deg. F in 30 minutes or less

Supports: Supports for internal shelving

Misc. ASME Code vessel, National Board certified.

This system is a second hand autoclave built in 1994 and it is a pressure vessel mounted on a skid, with a vacuum pump and control panel attached. The 18″ diameter workspace is 24″ deep and has supports for internal shelving. The autoclave is vertically oriented with all piping and wiring. A manual door to access the work zone is included. To open will require a number of nuts to be removed and then a hydraulic cylinder will be operated to lift off and swing the door. The heaters are externally mounted strip heaters mounted around the circumference of the pressure vessel. They are rated 36KW, 480 V, 3 phase, and sized for heating.

Cooling is accomplished with tubing attached to the exterior of the pressure vessel through which water and air flow. The Control System is a Nema 12 control panel attached to the unit.

PLEASE CALL US FOR MORE INFORMATION AT 606-677-2616 OR EMAIL US AT SALES@BONDTECH.NET</a

(SOLD)

Manufacturer: Bondtech

Date of manufacture: 2013

National Board #: 776

Working area: 8’ ID x 20’ Long

Temperature: 500°F

Pressure: 165 psig

Vacuum Lines: 12

Thermocouples: 24

Vacuum Pump: 4 HP

Controls: Allen Bradley PLC w/ Bondtech EnVision software

Includes (1) chamber and (1) floor cart

Special Notes: This system is complete and ready for immediate sale. Currently located at our facility in Salisbury, North Carolina

Sale Price: (As-is, Where-is)

Inspection visits are welcomed and encouraged