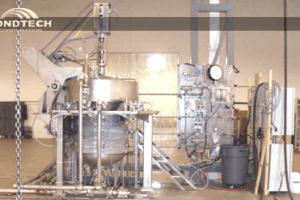

New Systems for removal of Ceramic Inserts Caustic Autoclave

Core-Leaching Autoclaves

The Bondtech Core Leaching and removal system, is a self-contained high pressure, high temperature capable caustic autoclave system, utilized in the removal of ceramic inserts from high nickel alloy investment castings. Each system is custom designed for the application and the product processed

BONDTECH BCL31x36 (Typical System)

Chamber dimensions: Vessel Size 31″IDx36″ Deep Autoclave Vessel Work Area 28″IDx28″ Deep Autoclave Vessel

Vessel Construction:

The Bondtech Autoclave will be a heavy commercial grade autoclave. It will be designed and manufactured in strict accordance to the ASME and National Board of Boilers and Pressure Vessel Inspectors code. The Bondtech autoclave will be designed in accordance to your specifications and requirements. Corrosion resistant materials are used throughout the vessel to provide longevity and reliability during the systems life time.

Heating and Insulation System:

The Bondtech heating and insulation system is properly sized to meet the design temperature requirements:

UN Zoned band type heaters with SCR control

Multiple zones independently controlled

Interlocked with the fill and drain of the vessel

Easy to service siliconized insulation blankets.

Each zone is individually power fused to provide high reliability and safety.

Temperature Monitoring Devices:

Thermocouple Type K on each zone for heater over temperature

Thermocouples Type K for internal vessel process temperature control

Exterior:

Non corrosion resistant material surfaces

Painted with heat and corrosion resistant primer and paint

Chamber Pressure:

Chamber pressure transducer

Actuated chamber pressure valves

Compressed air or nitrogen provided by customer

Basket and System Agitation:

A heavy duty corrosion resistant basket for holding working parts for processing.

A positive engagement latch system to remove the operator involvement in attaching the basket to the agitator

Automated agitation is set by the control system

Vertical agitation of the loaded basket is available for processes requiring the movement of the charged caustic to clean the surfaces.

Agitation rates and dwell times are programmable

Systems can be purchased without agitation

Requires no operator action to interface the basket to the agitator

Safety Valves, Attachments and Alarms:

Cycle drain active alarm

Drain Quench tank over-temperature alarm

Vessel over-temperature and over-pressure alarm

Safety relief and Rupture disk

Pressure switch for high and low pressure alarm

Door position limit switches

Cycle drain active alarm

Drain Quench tank over-temperature alarm

Vessel over-temperature and over-pressure alarm

Controls

Allen Bradley CompactLogix PLC programmable control system including system to download data for autoclave control with the following features:

Control heating ambient to 900˚F.

Run at precise temperatures for programmed time period from a type K thermocouple inputs

Run at precise pressures for programmed time period from a transducer input

Aautomatic control of cycle sequences from start to end

Operator controls for locking and unlocking door

Process complete and ready to open door indicator lights

Temperature and pressure safety back-ups

Full program editing and storage capabilities

On/off control of pressure from transducer

On/off control of caustic transfer pump

Control features

Utilizes a “State of the Art” Multi-tasking PLC processor

Programmed using IEC compliant programming software

The PLC system is completely industrially hardened

Industry standard Allen Bradley components

Industrial grade IO with built in opto-isolation

Standard IO interface types are used throughout the system 24VDC, 120VAC, 4-20mA, 0-10VDC, and ISO type TC inputs.

PLC programming contains a true ‘Logic Engine’ to determine the step to step transitions.

Completed profile data download capabilities

Multiple process conditions can be evaluated to satisfy the step change criteria