Industrial autoclaves are specialized containers designed to sterilize, cure, or strengthen objects using high temperatures and pressure. They are used for a variety of applications, from sterilizing medical equipment to curing composite components, vulcanizing rubber, laminating glass, and treating wood. Based on the intended application and system design, autoclaves may use either electric heat or steam to raise the temperature within the enclosure.

At Bondtech Corporation, we are committed to providing our customers with dependable, high quality autoclaves for an array of uses. With the recent COVID-19 pandemic, it is more important than ever for medical facilities to have a reliable way to decontaminate medical equipment and waste. To effectively and efficiently handle the pandemic, many hospitals and medical facilities have turned to on-site autoclaves.

Bondtech has risen to the challenge by providing small and affordable autoclaves to help hospitals prevent the spread of viruses, fungi, bacteria, and other infectious pathogens that can compromise the health and safety of patients and medical workers alike. In addition to medical facilities, Bondtech’s autoclaves have been incorporated into travel operations, such as airlines and trains, where viral spread is a concern. Waste products in transportation equipment can be sterilized on-site, reducing the potential for spreading illness to passengers and crew members.

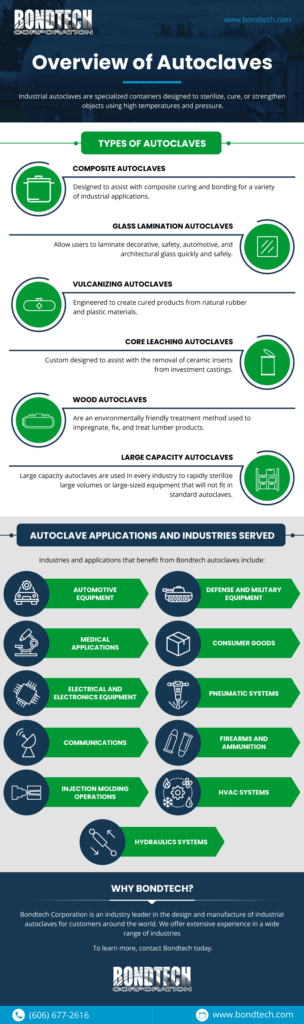

Types of Autoclaves

Types of Autoclaves

Bondtech is pleased to offer a host of autoclave designs for everything from medical equipment sterilization to ceramic core leaching. Below is a summary of our most popular autoclaves.

Medical Waste Autoclaves

Bondtech’s medical waste autoclaves are specialized heat-treatment units designed to eliminate microorganisms and pathogens, including the virus that causes COVID-19. By treating batches of medical waste with our chemical-free autoclaves, medical facilities can manage waste safely before disposing of it in a landfill.

Composite Autoclaves

Bondtech’s composite autoclaves are designed to assist with composite curing and bonding for a variety of industrial applications. We are committed to providing dependable quality, with unique designs specifically built to ASME Boiler and Pressure Vessel Code standards.

Glass Lamination Autoclaves

Our selection of glass laminating autoclaves allow users to laminate decorative, safety, automotive, and architectural glass quickly and safely. Bondtech’s glass laminating autoclaves are designed to facilitate fine control of every aspect of the glass lamination application.

Vulcanizing Autoclaves

Bondtech’s full line of vulcanizing autoclaves are engineered to help rubber manufacturers create cured products from natural rubber and plastic materials. Our vulcanizing autoclaves come with indirect electric heat, as well as direct and indirect steam heat configurations.

Core Leaching Autoclaves

Core leaching autoclaves by Bondtech are custom designed to assist with the removal of ceramic inserts from investment castings using a contained high-pressure, high-temperatures system specifically engineered for the application at hand.

Wood Autoclaves

Bondtech’s wood autoclaves are an environmentally friendly treatment method used to impregnate, fix, and treat lumber products. Our state-of-the-art EnVision process control system allows users to ensure that saturants completely reach the interior of the wood product, thereby extending the life of treated wood products.

Large Capacity Autoclaves

Large capacity autoclaves are used in every industry to rapidly sterilize large volumes or large-sized equipment that will not fit in standard autoclaves. They are used to enhance large-scale and high-volume sterilization processes for everything from medical and pharmaceutical equipment to food processing.

Autoclave Applications and Industries Served

At Bondtech, we pride ourselves on providing superior autoclave solutions for customers in many different industries. Whether you need glass lamination for automotive manufacturing or medical waste treatment, we have the knowledge and experience necessary to create custom autoclaves for your application. Industries and applications that benefit from Bondtech autoclaves include:

- Automotive Equipment

- Defense and Military Equipment

- Medical Applications

- Consumer Goods

- Electrical and Electronics Equipment

- Pneumatic Systems

- Communications

- Firearms and Ammunition

- Injection Molding Operations

- HVAC Systems

- Hydraulics Systems

Why Bondtech?

Bondtech Corporation is an industry leader in the design and manufacture of industrial autoclaves for customers around the world. We don’t just make machinery; we also custom design and manufacture equipment to meet even the most detailed and specialized specifications. In addition, we are capable of rebuilding and servicing existing machinery from every brand, not just our own. No matter how complex your system, we will refurbish and rebuild your autoclave so that it looks and operates like new.

With extensive experience in a wide range of industries, we understand the technical requirements of each system as a whole, which is why we are the industry’s premier provider of new and refurbished autoclaves and pressure vessels. We use only the latest technology to ensure that each system meets and exceeds industry standards and customer expectations.

To learn more about our extensive selection of autoclaves, pressure vessel solutions, and services, contact Bondtech today or request a quote for your next project.

Autoclaves

Autoclaves

Lamination

vulcanizing

Leaching

Autoclaves

Frequently Asked Questions

At Bondtech Corporation, we have been manufacturing reliable, high quality autoclaves for over 30 years. Here are some frequently asked questions:

Types of Autoclaves

Types of Autoclaves