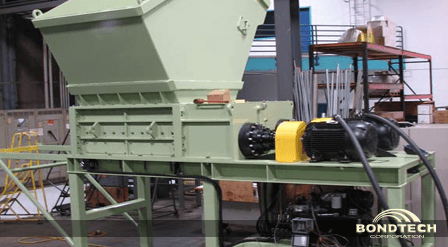

Shredding Systems for Waste Management

Hazardous Waste • PCB Contaminated Materials • Radioactive Waste • Chemical Weapons • Medical Waste

Our test and R&D facilities provide customers and the BONDTECH Corp. engineers with the technical base to design and manufacture custom reduction systems. Throroughly tested systems reduce start-up and commissioning costs,and ensure 100% reliability in the field. These shredder solutions include one-stage and two-stage solutions.

BONDTECH’s Medical Waste Reduction System automatically collects, reduces and conveys the sterilized waste material to a compaction chamber or cart. This two stage system safely and securely handles bags, boxes, and cartons of waste including plastics, paper, steel, and aluminum for hospital environment or regional waste facility.

BTT M55 Shredders

- Available in both electric and hydraulic versions

- High-torque, low-speed design

- Direct drive motor

- Alternate speed and torque combinations available.

- Auto reversal feature

- Patented ACLS – Advanced Cutter Locking System

- Shock load protection feature

- Proprietary bearing protection

- Convertible drive

- Versatile design accommodates electric or hydraulic drive

- Optional conversion package available.

BIT QUAD Shredders

- Heavy-duty Design

- Direct Drive

- Proprietary Bearing Protection

- Auto reversal

- Patented SSP (Severe Shock load Protection)

- Patented ACLS – Advanced Cutter Locking System

- Roll out screen design

- Produce particle sizes that range from 3/4″ – 6″

- Material Separation & Recovery

- Fuels – wood, paper, tires, plastics

- Product Destruction – electronics, plastics, paper, manufacturing