Aerospace • Motorsport • Nuclear • Ballistic • Concrete • Glass

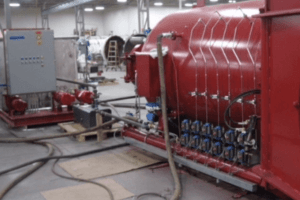

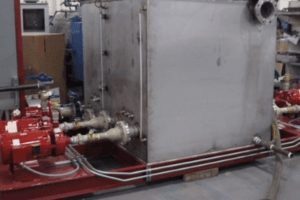

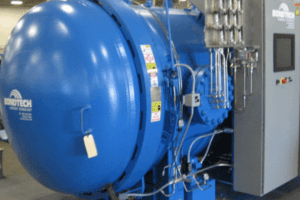

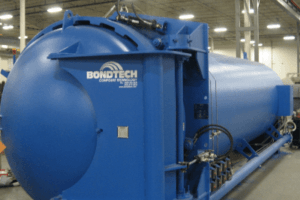

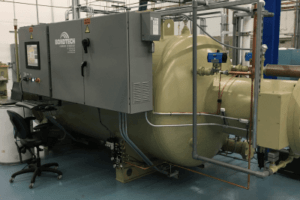

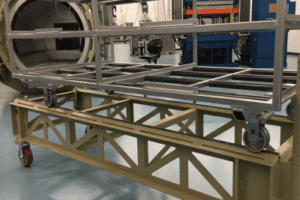

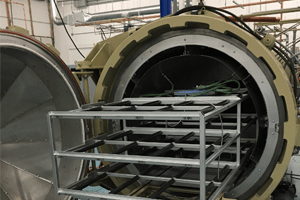

With experience partnering with various companies throughout the globe, Bondtech has engineered and developed autoclaves for advanced composites across multiple industries. This experience provides us with unique understanding that every production requirement is unique for composite autoclaves and build according to ASME Boiler and Pressure Vessel Code standards. Bondtech’s design patterns take into account specific composite curing and bonding requirements for any size and scope. Making us a full fledged custom composite autoclave manufacturer on top of our line of standard composite autoclaves.

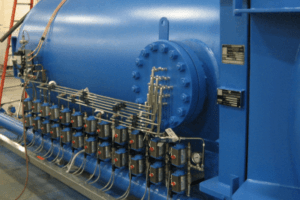

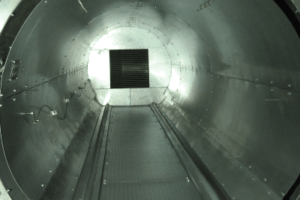

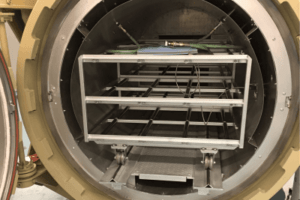

Bondtech’s composite autoclave systems also include key components in efficiency and precision that is expected from industrial autoclaves. Hodge International’s world renowned autoclave Quick-Opening Door system is included on most Bondtech composite autoclaves in addition to standard features, such as:

- Precision process controls

- High-grade automated vacuum systems

- Temperature monitoring and controls

- And many more

Get a Customized Composite Autoclave Quote

Autoclave Composite Design

Our first priority at Bondtech is maintaining the highest standards on all the autoclaves we produce. We dedicate ourselves to quality control efforts in five essential areas of autoclave composite design.

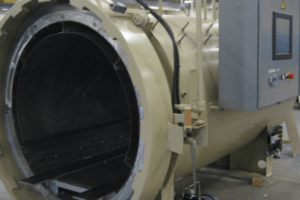

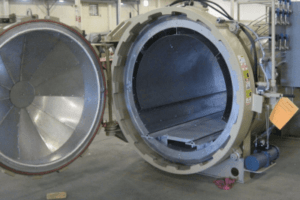

Safety

The high-pressure, high-temperature environment produced inside an autoclave can be dangerous, so safety a high priority in our Bondtech autoclave designs. Ensuring failure safety requires incorporating the following features:

- Door that will not open until atmosphere and temperature are at a safe level

- Warning system that informs the operator of any residual pressure prior to door opening

- Prevention of violent opening of the autoclave due to residual low pressure

- Door will not open until pressure has safely ventilated

- Autoclave pressurization cannot begin until door is fully locked

By designing our autoclaves with these factors in mind, we ensure workplace safety and prevent operator accidents.

Temperature

When resin systems are present, temperature control is a critical feature. Our temperature control system allows for full control of curing processes to meet the specified the criteria unique to composite materials. A range of precision heating, dwelling, and cooling gradients are provided with our systems.

Pressurization

Like our temperature control systems, the pressurization control systems used in our autoclaves allow full control over each stage of pressurization, providing a wide range of precision pressurization, dwelling, and depressurizing gradients.

Vacuum Control

Vacuum control monitors bagged precision components, identifying bursting conditions that might introduce volatile substances into the bag for the purpose of isolation. In addition, our vacuum control design allows for variable draw levels to suit the needs of specific applications.

Digital Process Control

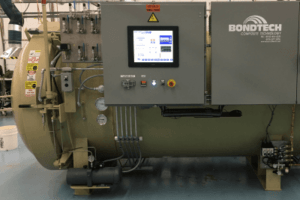

Besides providing safety warnings and control of temperatures, pressurization, and vacuum, our computerized process control systems allow for precise process monitoring, cure optimization, and real-time data logging.

Autoclave Manufacturing for Aerospace

In addition, growing demands for efficiency and cost improvements in aircraft manufacturing mean that autoclave designs must meet diverse and complex design requirements suited to both thermoset and thermoplastic composite materials. Our autoclaves address the challenges of the aerospace sector in a variety of ways, such as:

- Bondtech’s designs allow for state-of-the-art process controls for cure optimization, improving cost-effectiveness without sacrificing quality.

- Our composite autoclaves follow the highest possible standards in quality construction. All our vacuum system tubing is stainless-steel in design and is standardized on all composite autoclaves.

- Our systems are constructed within multiple international standards in mind, including (but not limited to) ASME, UL, CE/PED, and others.

- Bondtech’s EnVision control system offers the latest advancements in composite precision process controls and testing systems. Our control system complies with all current and known future requirements of governmental agencies such as the FAA, EASA, and all OEM aerospace composite parts requirements (i.e. Airbus AIPI-03-02-019 & AP-3222-E, Boeing).

Our design and manufacturing processes meet or exceed the demands of the aerospace industry in accordance with several qualified codes, including:

- Boiler and Pressure Vessel Code ASME Section VIII, Division I,

- American Society for Testing Materials (ASTM)

- American Institute of Steel Construction (AISC)

- “R” Stamping by National Board of Boilers and Pressure Vessel Inspectors

The Bondtech Standard

Our design and manufacturing processes meet or exceed the demands of the aerospace industry in accordance with several qualified codes, including:

- Boiler and Pressure Vessel Code ASME Section VIII, Division I,

- American Society for Testing Materials (ASTM)

- American Institute of Steel Construction (AISC)

- “R” Stamping by National Board of Boilers and Pressure Vessel Inspectors

Maximized Performance

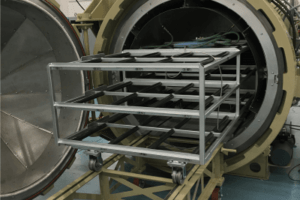

Our composite autoclaves incorporate pressurization and crosslinking to properly cure thermoset materials. The cure process includes a two-step process:

- Pressure is applied in a vacuum as the temperature is raised to a moderate level and maintained for a short period of time.

- Following this, the temperature is raised to the final cure temperature to complete the curing reaction.

The manufacture of composite autoclaves requires advanced components, attention to detail, and strict adherence to quality control standards. Our dedicated team of design, production, and quality control personnel dedicate themselves to the highest level of performance in producing composite autoclaves that perform according to the specifications of our clients.

For more information about the composite autoclave solutions provided by Bondtech, please request a quote from one of our experts.