Bondtech Rubber Vulcanizing

Autoclaves are large chambers that employ high pressures and temperatures to facilitate industrial processes. They are generally used to expose equipment and supplies to high-temperature saturated steam for decontamination or sterilization applications. However, they also have many other uses, such as in vulcanization operations.

Vulcanization is a chemical process applied to rubber or other natural compounds with elastomeric properties. Industry professionals use it to increase the elasticity and decrease the plasticity of the material, resulting in improvements to many of its physical and performance characteristics, such as resilience, tensile strength, viscosity, hardness, and weather resistance. Vulcanizing autoclaves—also known as vulcanizers—facilitate this process, enabling rubber manufacturers to quickly and easily convert natural rubber and plastic into cured parts and products.

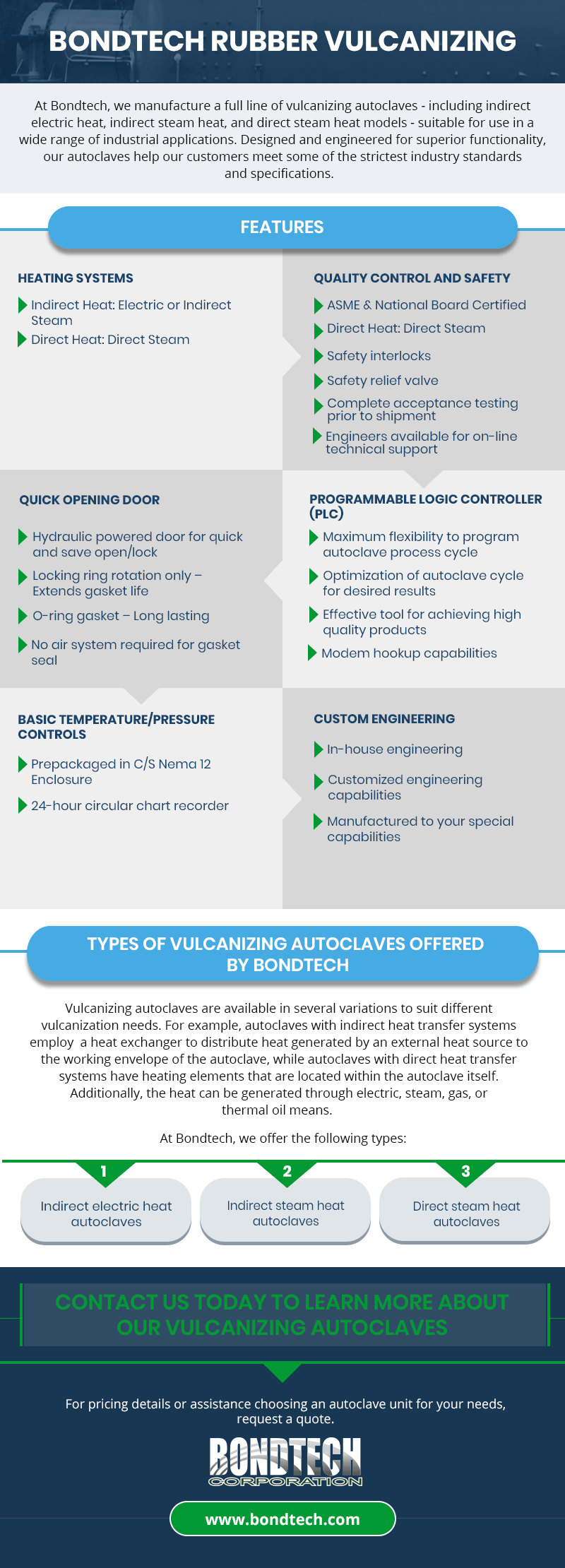

At Bondtech, we manufacture a full line of vulcanizing autoclaves—including indirect electric heat, indirect steam heat, and direct steam heat models—suitable for use in a wide range of industrial applications. Designed and engineered for superior functionality, our autoclaves help our customers meet some of the strictest industry standards and specifications.

Features

Heating Systems

- Indirect Heat: Electric or Indirect Steam

- Direct Heat: Direct Steam

Quick Opening Door

- Hydraulic powered door for quick and save open/lock

- Locking ring rotation only – Extends gasket life

- O-ring gasket – Long lasting

- No air system required for gasket seal

Quality Control and Safety

- ASME & National Board Certified

- Safety interlocks

- Safety relief valve

- Complete acceptance testing prior to shipment

- Engineers available for on-line technical support

Basic Temperature/Pressure Controls

- Prepackaged in C/S Nema 12 Enclosure

- 24-hour circular chart recorder

Programmable Logic Controller (PLC)

- Maximum flexibility to program autoclave process cycle

- Optimization of autoclave cycle for desired results

- Effective tool for achieving high quality products

- Modem hookup capabilities

Custom Engineering

- In-house engineering

- Customized engineering capabilities

- Manufactured to your special capabilities

The specifications of a vulcanization operation depend on the type of rubber or plastic employed. For example, silicone curing generally occurs at room temperature while tire rubber curing happens at temperature up to and exceeding 350° F. In addition to temperature, the material being processed also affects the length of the curing process. In many cases, process cycles are longer than required to ensure that all items in the batch are fully cured.

Once a vulcanization operation commences, it typically undergoes the following stages:

- Loading the component into the autoclave

- Establishing all necessary utility connections to the autoclave

- Closing and locking the autoclave door

- Applying pressure until a set level is achieved

- Starting the circulation fan and heating element

- Once the desired temperature is reached, maintaining it for the required processing duration

- Cooling the internal environment to a set value

- Halting circulation and depressurizing the autoclave

- Removing the processed component from the autoclave

BONDTECH vulcanizing autoclaves enable operators to set cycle parameters to precise settings to accommodate a variety of temperature, pressure, and cycle time requirements.

Types of Vulcanizing Autoclaves Offered by Bondtech

Vulcanizing autoclaves are available in several variations to suit different vulcanization needs. For example, autoclaves with indirect heat transfer systems employ a heat exchanger to distribute heat generated by an external heat source to the working envelope of the autoclave, while autoclaves with direct heat transfer systems have heating elements that are located within the autoclave itself. Additionally, the heat can be generated through electric, steam, gas, or thermal oil means.

At Bondtech, we offer the following types:

- Indirect electric heat autoclaves

- Indirect steam heat autoclaves

- Direct steam heat autoclaves

Features of Vulcanizing Autoclaves Offered by Bondtech

Our line of vulcanizing autoclaves incorporates several design features aimed toward facilitating operations for customers. Key features include:

Heating Systems Options

We offer vulcanizing autoclaves with three different types of heating systems: direct heat through the use of steam, indirect heat utilizing steam, or indirect heat generated by electricity.

Quick Opening Door

Bondtech autoclaves have hydraulic powered doors that allow for quick and safe opening and locking of the unit. The door systems feature a long-lasting O-ring gasket supported by a locking ring rotation only function that further extends its life. The use of an air system is not needed for the formation of an adequate gasket seal.

Basic Temperature and Pressure Controls

Each autoclave comes with a prepackaged temperature and pressure control unit. A 24-hour circular chart recorder is also included.

Programmable Logic Controller (PLC)

Programmable logic controllers (PLCs) provide autoclave operators with greater flexibility in the programming of autoclave process cycles. This quality allows them to optimize cycles to achieve the desired process and product results. The PLCs included in BONDTECH autoclaves have modem hookup capabilities.

Quality Control and Safety

At Bondtech, we understand the importance of quality and safety in autoclave operations. All of our autoclaves are equipped with state-of-the-art safety features and certified by the ASME & National Board. Additionally, before shipment, each unit is rigorously tested for quality. Even after delivery, our engineers are available for on-line technical support.

Contact the Autoclave Experts at Bondtech

At BONDTECH, we aim to provide our customers with the highest quality products and services for their autoclaving needs. Our in-house engineering team offers complete custom engineering and manufacturing capabilities to design, develop, and deliver an autoclave unit tailored to meet unique specifications.

Contact our team to learn more about our vulcanizing autoclaves. For pricing details or assistance choosing an autoclave unit for your needs, request a quote.