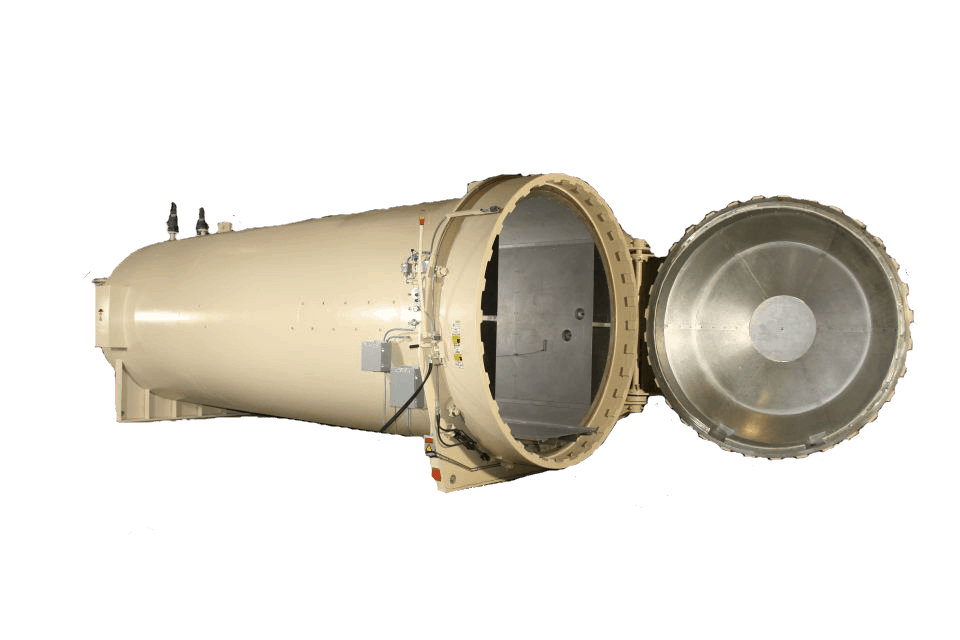

Glass Laminating Autoclave Systems

An autoclave typically uses steam heat to sterilize items. Usually, the process is performed with the intent of sanitizing potentially contaminated loads to make them safe for use in sensitive environments, such as research laboratories and medical settings. Glass laminating autoclaves operate in a similar manner but serve another purpose.

Glass laminating autoclaves create decorative, architectural, safety, and automotive glass in the safest manner possible. Bondtech’s line of glass laminating autoclaves can perform in accordance with virtually any manufacturer’s requirements. Operators can easily control every aspect of the glass laminating process. This includes curing different styles of glass, such as:

- Architectural

- Automotive

- Ballistic

- Tempered

Features and Benefits of Glass Laminating Autoclaves

Glass laminating autoclaves present a unique turnkey solution for any organization that regularly laminates glass. Bondtech autoclaves are ideal for both lab-scale work and high-volume production runs. Each autoclave is built and designed in accordance with custom specifications to ensure that the machine will function optimally in its application.

Glass laminating autoclaves feature efficient, reliable operation in any relevant application. They operate using computer control systems specifically programmed for laminated glass production. Pressure and temperature are controlled automatically, and safety protections such as door interlocks, operational alarms, and process control status alarms to ensure user safety are integrated into the equipment.

These machines also feature intelligent, optimized cycle processing to achieve maximum production efficiency. The implementation of a glass autoclave system allows an organization to achieve shorter cycle times, decreased energy costs, and a complete cure of laminated material. This ensures both durability and strength for end-users.

Laminated Glass– Definitions, Features, and Uses

Laminated glass is one of several types of safety glass. The material is created through the combination of annealed glass and either plastic or polyvinyl butyral (PVB). After being sealed between two glass pieces, the final product is formed via the “sandwich” of glass-plastic-glass. Some laminated glass is manufactured using just one layer of plastic, while other laminated glass products may include multiple glass and plastic layers.

Laminated Glass Features and Applications

The plastic or PVB that a manufacturer selects before beginning the fabrication process may be clear or tinted, depending on the intended application. Laminated glass is ideal for screening harmful UV radiation and also has beneficial soundproofing properties.

Common applications for laminated glass include:

- Automobile windshields

- Glass stairs and railings

- Glass facades

- Glass flooring

- Skylights

Bondtech: Your Glass Laminating Partner

Bondtech customizes each piece of machinery to the client’s operation and specifications, guaranteeing an optimal solution for any application. We strive to provide the best and most reliable autoclaving equipment on the market. We control the development of each autoclave from design through manufacturing and final testing to ensure it will perform optimally.

Bondtech’s glass laminating autoclaves offer the same level of reliability and functionality that customers expect of all Bondtech autoclaves. Quality and service are always our priority, and we’re ready to assist you in the selection of the best autoclave for your glass laminating application. For more information about our glass laminating autoclaves or any of our other products, please request a quote today!

Precision Engineering

The Glass Lamination industry relies upon the quality and precision of it’s industrial tools. Bondtech’s ASME certified glass lamination autoclaves deliver top quality on both counts. Built to custom specifications, Bondtech’s glass laminating autoclaves fit any manufacturing requirement, controlling every aspect of the glass laminating process. Contact us for a custom quote today.