Corporate Overview

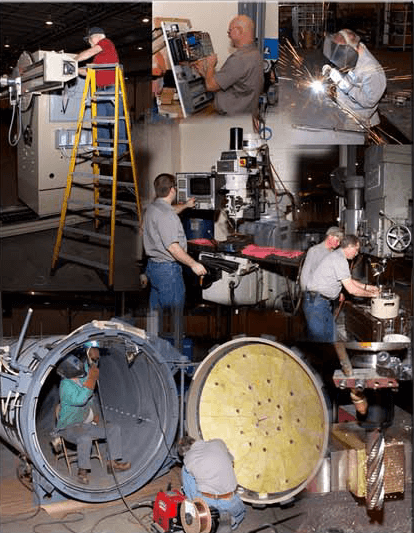

Bondtech Corporation doesn’t just sell machinery, we custom manufacture to specification, rebuild existing machinery, and service all brands of equipment, even our competitors.

Our experience in various industries allows for a higher knowledge of customer’s technical requirements. The reliability and dependability which is a must in the aerospace industry is a must in all of Bondtech’s autoclaves. Bondtech Corporation is a sole supplier of new and refurbished autoclaves and pressure vessels. The single source capability represents direct control starting with coordinated mechanical and metallurgical design through the final test of the complete system. Bondtech uses the most advanced technology to bring the autoclave up to today’s standards. When the autoclave is completed, the unit will not only look like new, but it will also perform and last like a new unit. When refurbishing a unit, we will take into consideration our customer’s unique requirements as well as budget considerations.

Mission and Value

Mission Statement

Making the world’s best Autoclave Systems can only happen with the US greatest employees. We take great pride in our work, and take great care to deliver exceptional Autoclave Systems and a positive ownership experience to our customers around the world. At the Bondtech Corporation we make a strong commitment to our customers, employees, partners and other important stakeholders. We state proudly our seven principles that guide Bondtech in everything we do:

- Safety first for workers

- Highest Quality

- Lifelong Customers

- Inventive and Innovative

- Delivering long-term investment value

- Making a constructive difference

- Working together effectively as one team