Bondtech MEDICAL WASTE CONTROLS

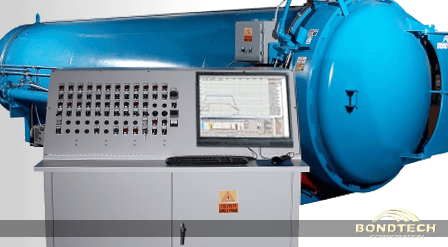

BTT PLC Control System

Bondtech Corporation’s high performance control and data acquisition systems have been thoroughly proven in high-tech aerospace manufacturing plants. The BTT PLC control system is designed to provide maximum flexibility to address any site specific waste treatment requirements.

BTT systems can be configured with the following options:

- Color Graphics Display

- Weight Scale Integration

- Hard Drive Data Acquisition

SuperMicro PLC

The FX3N Series PLC provides the function controls that automatically commands the process cycle steps for the autoclave system. Extensive data memory (over 8,000 Data Registers) for capturing real time operating parameters that continuously monitors autoclave system performance.

The FX3N Series PLC support on-line troubleshooting/programming functions, used in system development and commissioning. Remote programming/monitoring capability by modem provides for immediate technician support. This PLC system has the external data link integration capability for communication with other peripheral systems (PC, network, control systems, etc).

Powerful features include:

Windows Programming – Use Ladder, List or SFC languages.

Operator Interfaces – Flexible selection to match specific customer application

Extensive Program Memory – 8,000/16,000 steps

Enhanced Program Throughput – 80 nanoseconds/step

Embedded Motion Control – 20,000 hz pulse train, Trapezoidal ramp instructions

Flexible Configurations – From 16 to 256 I/O & extensive special function I/O capabilities